© BMWi / Herr Müller

Windows close automatically before it starts raining, heating units adjust room temperatures to the daily rhythms of occupants, automobiles automatically reduce their speed near schools and garbage containers send signals to municipal authorities that they are full – this is the Internet of Things. This is the capability of each device to communicate with the Internet and other devices using modern information and communications technology. A digital revolution with substantial implications – for our personal lives, our daily work, and also for the way in which companies communicate, now and especially in the future. The Internet of Things is also the basis for Industry 4.0 and smart manufacturing.

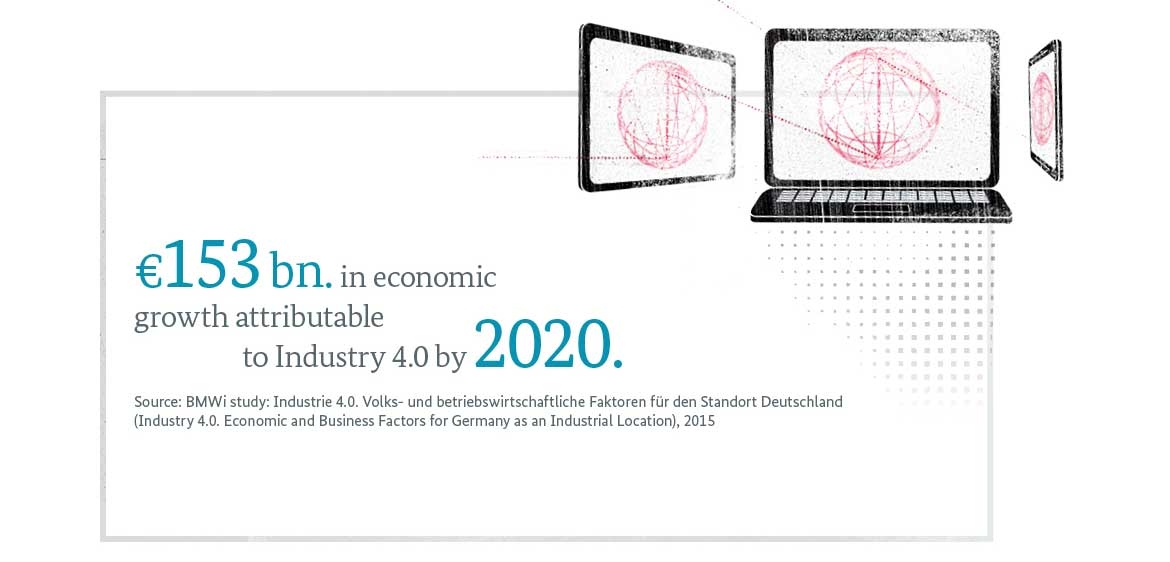

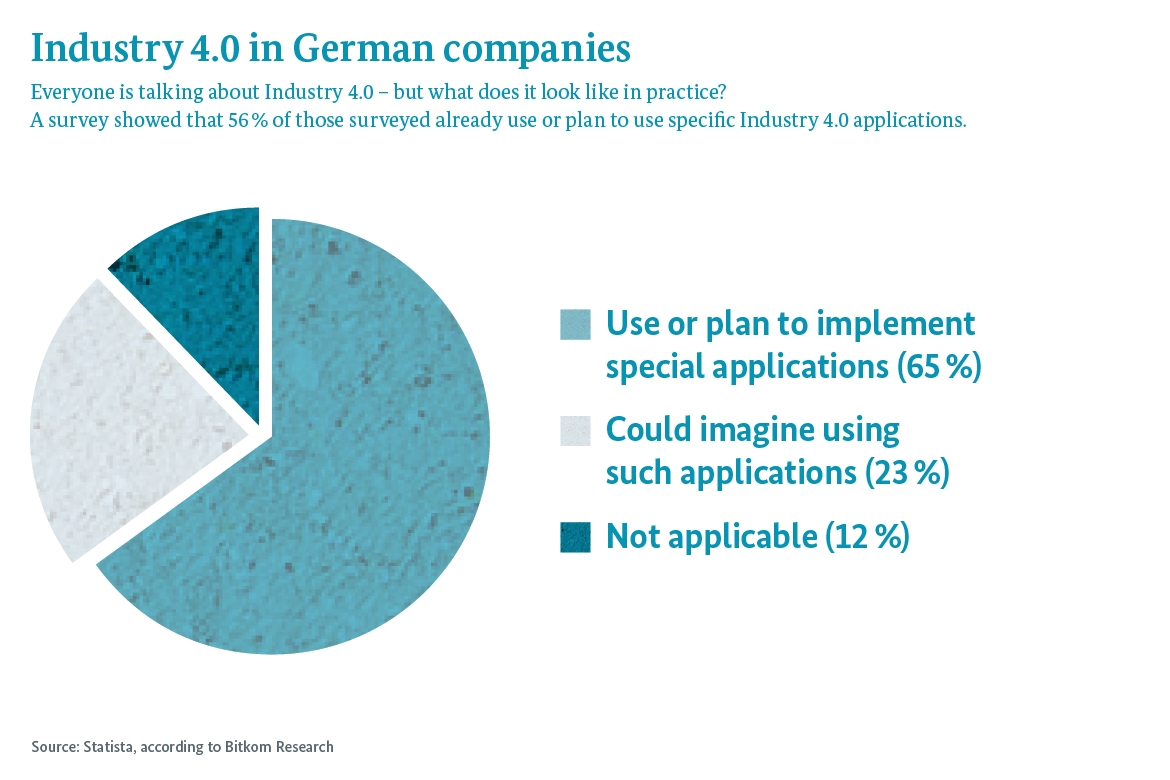

Industry 4.0, the Industrial Revolution and Digitalisation of Industry are catchwords for this development. What they mean is the melding of the physical world of machines and plants with the digital world of bits and bytes. Production is integrated with information and communication technology: working conditions improve, and new jobs and innovative business models are created.

© BMWi

Mass production with high quality standards

Musli with quinoa instead of oatmeal, cranberries instead of raisins, and absolutely no nuts? Up until recently consumers had to look long and hard for the right product, or buy the individual ingredients and mix them by themselves, in order to satisfy their special wishes. Today the consumer can order their favorite cereal combinations online and cheaply at home at their computers – the same goes for configuring jogging shoes, customizing furniture or ordering sports articles manufactured by 3D printers. Industry 4.0 combines the advantages of mass production with the special requirements of custom manufacturing. This has an enormous impact on productivity, customer loyalty and competitiveness.

German companies are in the lead internationally in this regard and are very competitive. They are familiar with customer demand and are leading in Industry 4.0 technologies. The Federal Ministry for Economic Affairs and Climate Action provides a significant contribution to digital transformation of manufacturing with its Platform Industry 4.0, one of the world’s largest networks of companies, government, trade unions and research institutes.

© BMWi

Important prerequisites: norms, standards and interoperability

In order for individual components such as machines and sensors to communicate with each other in the Internet of Things, reliable interfaces are absolutely necessary. This interoperability – that is, independent systems and technologies are capable of working together seamlessly – requires us to introduce uniform international norms and standards. Machines must be able to communicate cross-border, so that companies can manufacture globally.

For this reason, Germany is using its G20 presidency to forge an international consensus on norms and standards for four central topics: Industry 4.0, IT security, smart cities and smart mobility. This also includes involving the G20 countries in defining important principles of international standardisation, such as interoperability and transparency. The global Internet of Things can only function if everyone agrees on uniform international frameworks and interoperable solutions.

| What is a smart factory? |

|---|

| In a factory 4.0 machines autonomously coordinate manufacturing processes, service robots work together with humans in smart assembly steps, driverless transportation vehicles handle logistics tasks. In addition, tools, machines or transportation means are outfitted with digital “eyes and ears” (sensors) as well as “hands and feet” (actuators) and controlled using central IT systems. In this manner, smart transportation containers can transmit by radio link information regarding their contents and their current location in the factory. This relieves the workload for production and logistics. |

![To homepage Logo [EN]de.digital](https://www.de.digital/SiteGlobals/DIGITAL/StyleBundles/Bilder/sublogo_en.png?__blob=normal&v=1)